Most scaffold erections require some simple form of lifting device to raise and lower material to the required working height. Gin wheels are one of the most commonly used devices used in scaffolding with “ring type” variety of wheels typically used; these types of wheels have a ring fitting with swivel connection which allows the ring to slide over a supporting tube.

A “ring type” gin wheel should be secured and supported correctly when fitted to an independent scaffold. A horizontal tube should be used to support the gin wheel, the horizontal tube should be connected across 2 standards of the independent scaffold (inner and outer) which project above the top lift where materials are been raised, the horizontal support tube should be connected to these standards using a right-angle double coupler one at each standard. If a joint is present to the inner standard between the gin wheel horizontal support tube and the lift below, this connection should be made with a sleeve coupler rather than a joint pin, to resist lift.

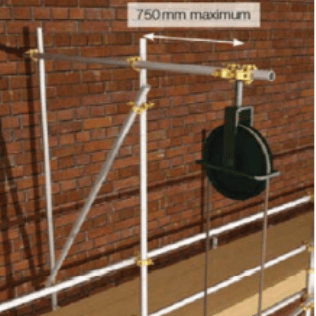

The point at which the gin wheel is suspended from the horizontal support tube should be no more than 750mm from the outer standard of the scaffold to avoid over loading, the loading on the gin wheel should not exceed 50kg mass. When the gin wheel is in position it should be prevented from moving along the supporting tube by securing right angle couplers to either side of the wheel.

Operatives tasked with using gin wheels and ropes should have received suitable training to use the equipment. (Suitable training is given via CISRS training courses but for those below this level, typical requirements may include certificated manual handling and Safety Gin Wheel & Rope training from a competent trainer). The employer should also monitor their attitude and aptitude towards safety and Gin Wheel & Rope work and ensure adequate supervision

Gin wheels must be thoroughly inspected every 12 months as per Lifting Operations and Lifting Equipment Regulations (LOLER) and all accessories (including ropes) inspected every 6 months. Copies of inspections must be retained.

When a gin wheel and rope are in use then pre use checks should be carried out at the start of every work shift and then the equipment should be continually monitored throughout the shift, these checks should be made by a competent person (CISRS Scaffolder).

Until the scaffold is handed over – the equipment must have a weekly recorded inspection by a competent person (e.g., a CISRS Scaffolder or a CISRS Scaffold Inspector). If the gin wheel and rope are then handed over as part of the scaffold on the request of the client the Gin Wheel & Rope then becomes part of the scaffold and is subject to statutory inspection as part of the weekly scaffold inspection regime to which it is recommend the scaffold contractor makes the client aware of the required statutory duty to inspect the gin wheel and rope equipment.

The NASC however, recommends that gin wheels and ropes are removed from handed over scaffolds and removed from site to prevent the equipment from being abused.

To download the ScaffTalk PDF, click here.